Nantero’s NRAM, A Universal Memory Candidate?

Every year at Hot Chips, there is usually that one presentation that arouses our curiosity far beyond the rest. This year it was Nantero and their NRAM technology. A non-volatile memory technology with a data retention of 12,000 years, a very wide operating temperature range, incredible performance, and seemingly unlimited scaling. If that wasn’t enough, it seems to have no real gotchas; at least none that we or the other attendees at the symposium could find.

“Carbon nanotube memory; it sounds so sexy I feel like I should just shut up and not say anything,” said Bill Gervasi, principal systems architect at Nantero, in his opening statement for his NRAM presentation.

In case you have never heard of them, Nantero is an IP design house. Their business model is quite similar to ARM, licensing the technology and reference designs to other companies that make the chips. As you might expect, bringing a new type of memory to market takes decades and as such, they have actually been around for a fairly long time now developing this technology (since the early 2000s).

In case you have never heard of them, Nantero is an IP design house. Their business model is quite similar to ARM, licensing the technology and reference designs to other companies that make the chips. As you might expect, bringing a new type of memory to market takes decades and as such, they have actually been around for a fairly long time now developing this technology (since the early 2000s).

CNTs

Nanotube-RAM, as the name implies, uses carbon nanotubes as the switching medium. For brevity’s sake, we can describe carbon nanotubes (CNTs) as simply graphene sheets that have been rolled up into tubes. In other words, those are a hexagonal lattice of carbon atoms that have been rolled into cylinders. Therefore, we can conveniently talk about CNTs in terms of their length and diameter.

Resistance Change Memory

The basic mechanism behind an NRAM cell is the van der Waals effect, the same force that helps geckos walk up walls. This force keeps CNTs that are apart repulsive and CNTs that are touching, adhesive. Their repulsive and adhesive behavior is a function of the van der Waals distance. An electrostatic force is used to switch between the two states. Nantero exploits this exact behavior to form a non-volatile memory cell. When a sufficient amount of CNTs touch, the overall resistance drops. Likewise, when disconnected, the stochastic network exhibit very high resistance.

Bitcell

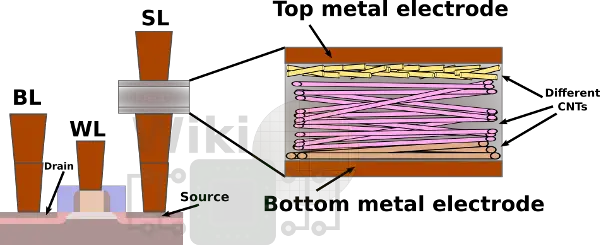

Building an NRAM bitcell is relatively simple. The FEOL is built in any way you desire. In the back end, metal contacts are exposed where you want them. The carbon nanotube slurry is then spin coated on top of those structures. The process completes with a bake and the top metal electrodes. The CNTs on the parameter of the cell are permanently fixed to form a protective barrier, preventing top metal from permeating into the cell and shorting it.

The cell is dielectric-free and has shown no wear-out. Since it doesn’t matter what’s below, the possibilities are quite intriguing. The type of transistor used, its geometry, and its material does not matter. In fact, the substrate itself can differ as well (beyond silicon). A 0 is a result of high resistance across the two electrodes. Likewise, a 1 is a result of low resistance across the two electrodes. Nantero reported over 10x difference between an on and an off so detection should not be difficult. This also means there is no need for calibration across the wafer.

Part of Nantero success working with carbon nanotubes appears to stem from how they treat an NRAM cell as a whole. Problems with converting raw CNT to electronic-grade CNT comes from the imperfections and other amorphous carbon structures in the mixture which can modify the properties of the CNTs. Nantero claims to have developed a straightforward and reproducible purification process which can be brought to mass production. Additionally, whereas traditionally, large-scale CNT-based integration attempted to build complex precise CNT structures, Nantero forgoes the idea of discrete structures by working with a fabric of random CNTs of no particular orientation. Operations are that of the stochastic mesh of hundreds to thousands of nanotubes which is simply deposited uniformly onto wafers using standard foundry tools. It’s this simplification that allows them to overcome many of the usual CNT assembly problems.

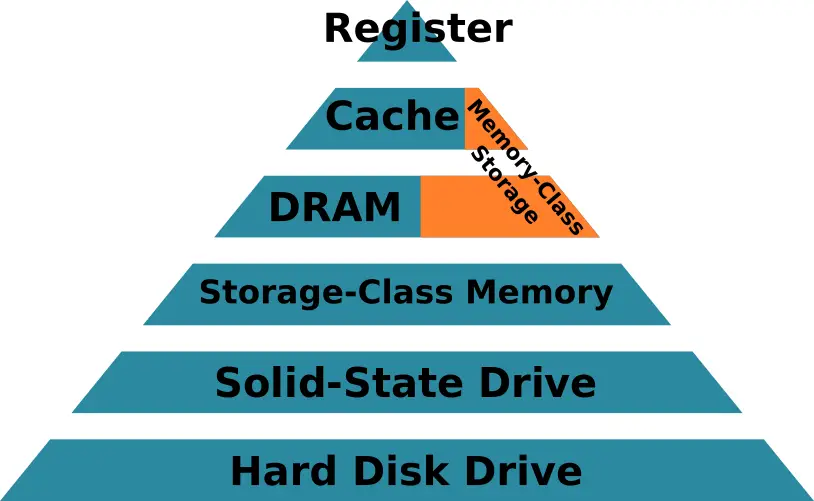

Memory-Class Storage

If you’ve been following Intel on their journey to commercializing 3D XPoint, then you’re probably familiar with the term storage-class memory (SCM). The term is used to describe a new class of emerging memory that bridges the latency gap and density gap between the two while staying non-volatile. That class includes things such as 3D XPoint, MRAM, and ReRAM. At Hot Chips, Gervasi proposed a different term – memory-class storage (MCS). The reason is simple: none of those storage-class memory types come close in performance to DRAM. MCS, on the other hand, describes a class of memory capable of DRAM-level of performance or better while remaining non-volatile.

The diagram above should give you a good idea of the kind of characteristics you can expect from NRAM. It’s very fast with a 5ns or less read/write access. That makes it fast enough to replace DRAM and possibly find interesting uses as another level of cache (low-level caches are a bit faster at 0.5ns). It’s got a data retention of around 12,000 years or under the worst condition (>300 °C) down to a few 100s making it ideal for harsh conditions such as automotive. Nantero has studied the endurance to well into the >10 trillions of cycles and the energy required to change the state of the cell is 5 fJ/bit, matching or beating DRAM (usually 5-7 fJ/bit). From a cost perspective, NRAM is also cheaper than DRAM (16Gb for $6 on 28nm, discussed later). By the way, if all of that wasn’t enough, NRAM is also particularly suited for aerospace application due to its immunity from charged particles.

It’s interesting to point out that Nantero doesn’t really see Intel’s Optane and similar technologies a direct competition. Instead, they view them as complementary technologies. This isn’t too surprising considering the performance characteristics of NRAM.

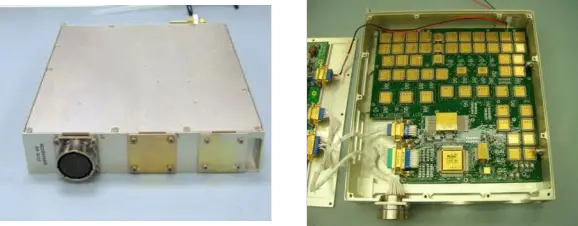

Rad Hard & Aerospace Applications

You often hear claims that CNTs and graphene can do just about anything but leave the lab. In reality, Nantero tells us this product is already out – at least in the aerospace market. In 2008, Lockheed Martin acquired the government-facing business unit of Nantero. They’ve also entered into an exclusive license arrangement with Nantero for government applications. At the time, around 30 employees from Nantero joined them, including Nantero’s co-founder and COO Dr. Brent Segal. In 2009, they jointly tested a radiation-resistant NRAM device in space as part of STS-125 (same space shuttle Atlantis mission that repaired and upgraded the Hubble Space Telescope). At the time, it was an important step in the development of NRAM-based devices for space applications.

–

Spotted an error? Help us fix it! Simply select the problematic text and press Ctrl+Enter to notify us.

–